New method measures 3-D polymer processing precisely

Phys.org | October 09, 2018

Recipes for three-dimensional (3-D) printing, or additive manufacturing, of parts, have required as much guesswork as science. Until now. Resins and other materials that react under light to form polymers, or long chains of molecules, are attractive for 3-D printing of parts ranging from architectural models to functioning human organs. But it's been a mystery what happens to the materials' mechanical and flow properties during the curing process at the scale of a single voxel. A voxel is a 3-D unit of volume, the equivalent of a pixel in a photo.

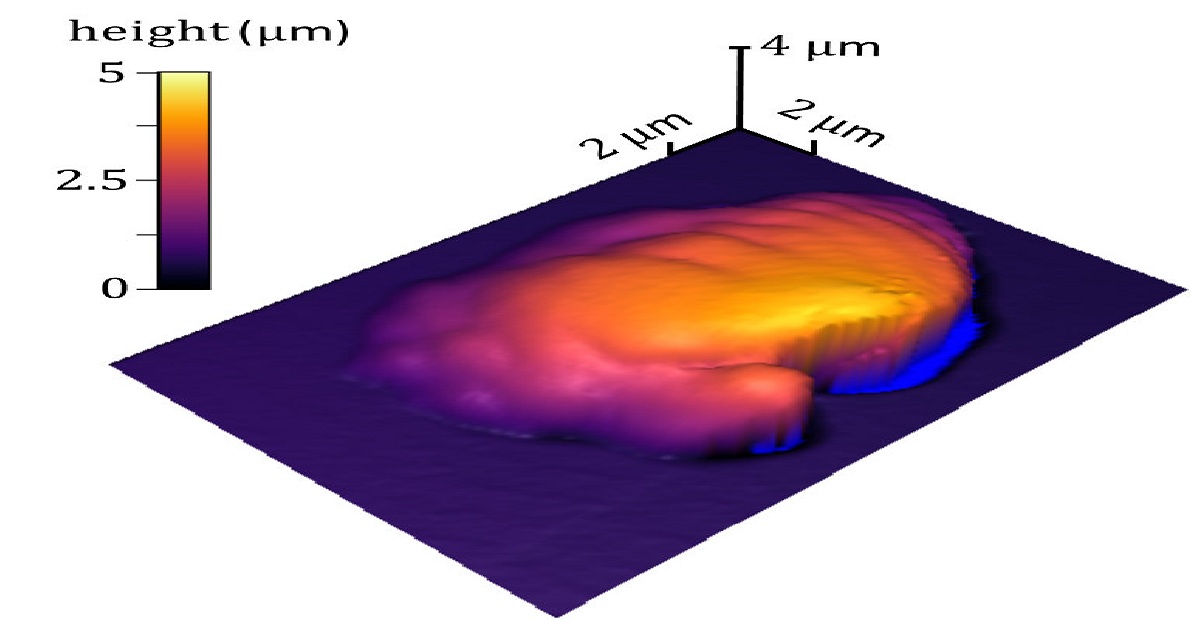

Now, researchers at the National Institute of Standards and Technology (NIST) have demonstrated a novel light-based atomic force microscopy (AFM) technique—sample-coupled-resonance photorheology (SCRPR)—that measures how and where a material's properties change in real time at the smallest scales during the curing process.